Early Stage Researchers (ESRs)

The Newfrac Computational Platform» collects the common computational tools and knowledge basis for the network. You will find here the progress of the work of the network and the related codes we develop to solve fracture mechanics problems.

Karthik Ambikakumari Sanalkumar

“As a crack to crack the cracks”: a dedicated researcher in fracture mechanics, striving to unravel the mysteries of crack initiation and propagation and provide solutions for brittle materials.

ESR01: Total energy minimization with stress conditions for mixed mode fracture in anisotropic heterogeneous materials and structures. See details»

Karthik is from Kerala, a state in southern India. He is an enthusiastic researcher with over two years of experience in numerical methods and a motivated engineering university postgraduate specialising in computer science and continuum mechanics.

He graduated with rank from Kerala University in 2015 with a BTech in Mechanical Engineering. After obtaining the MSc. in Computer Science in Engineering at TU Braunschweig, Germany, in May 2019, he worked as a research assistant at TU Berlin in cooperation with Fraunhofer IZM for almost a year.

He is currently a NewFrac ITN Early Phase Research Fellow (MSCA), working with Professor Vladislav Mantic (Sevilla) and Professor Marco Paggi (Italy), with his research interests focused on fracture mechanics.

Lucca, Italy // Duration: 5 months (March 2022 - August 2022)

- Object: Development of modelling strategies and their computational implementation. The code's outcomes will be contrasted against other numerical techniques, including Cohesive Zone Models (CZM) and Phase Field (PF) methods, in addition to experimental data drawn from various literature sources. This comparative examination will gauge the code's precision and dependability in representing diverse fracture phenomena.

- Personal Experience: During my research period at IMT School for Advanced Studies in Lucca, Italy, from March to August 2022, I had the opportunity to immerse myself in a vibrant research atmosphere. Collaborating with dedicated colleagues and accessing well-equipped laboratories greatly enriched my experience as I worked on developing modelling strategies and implementing them computationally.

Robert Bosch, Germany // Duration: 6 months (March 2023 - May 2023 and October 2023)

- Object: to validate the developed computational tools that solve industrial fracture problems in SFRP composites.

- Personal Experience: Additionally, during my time as ESR01 at Robert Bosch in Germany, from March to May 2023 and again in October 2023, I gained valuable insights into real-world industrial fracture problems in SFRP composites. My interactions with experts in the field and the hands-on experience in applying the developed computational tools were instrumental in broadening my research perspective and skills.

- Marie Skłodowska-Curie Actions (MSCA) Satellite Event, held in Katowice, Poland, 10th and 11th June, 2024

- EuroScience Open Forum 2024, held in Katowice, Poland, from 12th to 15th June, 2024

- NewFrac Conference – New Computational Strategies for Fracture, held in Porto, Portugal, from 07th to 10th May, 2024

- EUROMECH COLLOQUIUM 635 - Finite Fracture Mechanics held in Lyon, France, from 12th to 14th September, 2023

- CFRAC 2023 - Seventh International Conference on Computational Modelling of Fracture and Failure of Materials and Structures, held in Prague, Czech Republic, from 21st to 23rd June, 2023.

- ICF15 - 15th International Conference on Fracture, held in Atlanta, Georgia, USA, from 9th to 19th June, 2023

- NewFrac & TC16 Joint Workshop – “Reaching Out”, held in Torino, Italy, from 17th to 20th January, 2023

- FDM 2022 - 20th International Conference on Fracture and Damage Mechanics, held in Malaga, Spain, from 5th to 7th September, 2022

- ECF23 - European Conference and Summer School on Fracture 2022 held in Funchal, Madeira, Portugal, from 25th June 2022 to 2nd July 2022

- NewFrac Workshop 2 – “Expanding Horizons”, held in Lucca, Italy, from 09th to 12th May, 2022

- NewFrac Workshop 1 – “New Strategies in Computational Fracture Mechanics”, held in Seville, Spain, from 1st to 8th October, 2021

Dissemination

Moreover, I have taken part in the European Researchers’ Night during 3 years, an amazing opportunity to bring science closer to people who are not involved in the field.

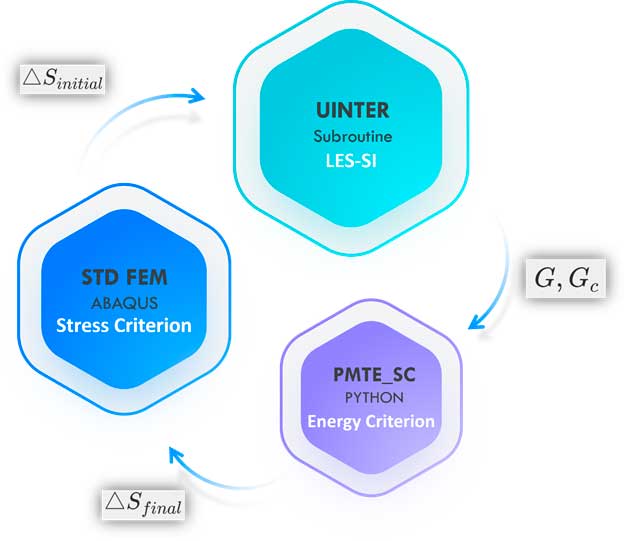

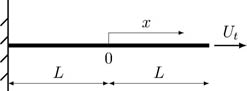

This PhD research project, assigned to Early-Stage Researcher (ESR) 1, aims to develop and implement a computational code based on the Coupled Criterion of Finite Fracture Mechanics (CCFFM) with the new formulation known as the Principle of Minimum Total Energy subjected to a Stress Condition (PMTE-SC). The code will be specifically designed to accurately predict the initiation and propagation of cracks in brittle materials.

The primary task involves the development of a computational code that incorporates the PMTE-SC algorithm to ensure the satisfaction of stress and energy conditions during crack advancement. The code will utilise a load-stepping algorithm to minimise the total energy change associated with crack growth. Cracks will be modelled as topological discontinuities within the finite element mesh, explicitly introduced during the domain discretisation and aligned with element edges.

A series of benchmark problems will be investigated to validate the developed code. These problems include mixed-mode crack propagation, scenarios involving multiple cracks, interface problems, and anisotropic materials. The results obtained from the code will be compared with other numerical procedures, such as Cohesive Zone Models (CZM) and Phase Field (PF) methods, as well as experimental results from various literature sources. This comparative analysis will assess the accuracy and reliability of the code in capturing different fracture phenomena.

This research project aims to advance the understanding and prediction of crack behaviour in brittle materials. Addressing various crack scenarios and considering factors such as mixed mode loading, multiple cracks, interfaces, and anisotropy will contribute to the comprehensive analysis of fracture mechanics. The resulting code will be a valuable tool for researchers and engineers, aiding the study and design of structures and materials susceptible to crack propagation.

In my Ph.D. research project, I'm developing a computational code that predicts the initiation and growth of cracks in brittle materials. I know that might sound a bit technical, but here's the gist: Imagine you have a glass or ceramic object, and you want to know how cracks might form and spread in it. That's what I'm studying.

The main goal of my research is to create a computer program that can accurately predict how these cracks will behave. We're using a unique algorithm called the Principle of Minimum Total Energy subjected to a Stress Condition, which is like a set of rules for how the cracks should grow. The computer program will be designed to make sure these rules are followed. To check if our program works correctly, we will test it in different situations, like when there are cracks in different directions or multiple cracks close to each other. We'll compare the results we get from our program with what other methods and experiments tell us. This will help us see if our program is good at understanding and predicting how cracks work.

We're doing all this to improve our understanding of how cracks form in things like glass, ceramics, and other brittle materials. This knowledge can be essential for engineers and researchers who design structures and materials that might crack over time. So, while it may seem a bit complicated, the end goal is to make things safer and better in the real world.

Expected Date: September 2025

My research contributes to several key EU policies. Firstly, it aligns with the EU industrial policy by aiming to enhance the competitiveness of EU industries. Through the development of a computational code that accurately predicts crack behaviour in brittle materials, my investigation supports the EU's goal of fostering innovation and growth within the industrial sector. This is particularly relevant as the EU seeks to lead in the transitions towards climate neutrality and digital leadership, where understanding and mitigating material weaknesses are crucial. Additionally, my investigation has relevance within Horizon Europe, the EU's framework program for research and innovation. By developing solutions to address policy priorities related to the green and digital transitions, my research supports the overarching aim of strengthening the EU's scientific and technological basis. It also contributes to tackling global challenges such as climate change and pollution, aligning with Horizon Europe's mission to address critical areas of concern.

In summary, my research contributes to EU policies by advancing knowledge in materials science and fracture mechanics, which in turn aids in the pursuit of industrial competitiveness, a unified research area, and innovation to address pressing societal and environmental challenges.

Simone Sangaletti

“Il più grande nemico della conoscenza non è l’ignoranza, ma l’illusione della conoscenza."

ESR02: Toughening composites by micro and meso structural optimization. See details»

Hello, my name is Simone, I am from Milan. I studied the Bachelor of Aerospace Engineering and then the Master in aeronautical engineering. I am now finishing my PhD at Universidad de Sevilla and I’m ESR02 in the NewFrac network.

ETH Zurich // Duration: 6 months (March 2022 – September 2022)

At ETH I focused the attention on the application of phase field modelling at the microscale for PEEK composite materials. The work has been carried out in collaboration with two departments: the Computational Mechanics group of Laura De Lorenzis and the CMAS lab of Paolo Ermanni. The work has been presented to the international conference ICCM2023 in Belfast. During the stay I had the occasion to meet all the guys from ETH and in particular Francesco (ESR10) and Camilla (ESR05) and to share with them not only theorems but also beers and parties!

Bottero // Duration 4 months (June 2023 – September 2023)

During this industrial secondment I have applied all the developments I have made during my PhD thesis. The stay was focused on the application of phase field modelling to study the fracture of bottles under vertical and pressure loading, given the actual geometry of the bottle including defects, obtained from tomographic techniques.

- COMPOSITES 2023 - 9th ECCOMAS Thematic Conference on the Mechanical Response of Composites, held in Trapani, Italy, from 12th to 14th September, 2023

- ICCM23 – International Conference on Composites Materials, held in Belfast, UK, from 30th July to 04th August, 2023

- CFRAC 2023 - Seventh International Conference on Computational Modelling of Fracture and Failure of Materials and Structures, held in Prague, Czech Republic, from 21st to 23rd June, 2023.

- NewFrac & TC16 Joint Workshop – “Reaching Out”, held in Torino, Italy, from 17th to 20th January, 2023

- ECF23, European Conference and Summer School on Fracture 2022 held in Funchal, Madeira, Portugal, from 25th June 2022 to 2nd July 2022

- NewFrac Workshop 2 – “Expanding Horizons”, held in Lucca, Italy, from 09th to 12th May, 2022

- NewFrac Workshop 1 – “New Strategies in Computational Fracture Mechanics”, held in Seville, Spain, from 1st to 8th October, 2021

Dissemination

Being part of the Universidad de Sevilla, I organized and took part in the European Researchers Night for two years. It was an amazing experience!

- “Fracture tailoring in 3D printed continuous fibre composite materials using the Phase field approach for fracture”, 2022, Composite Structures. https://doi.org/10.1016/j.compstruct.2022.116127»

- “Effect of tailored fiber deposition in 3D printed composites: application of an anisotropic phase field model”, 2023, TAFMEC. https://doi.org/10.1016/j.tafmec.2023.104030»

- "Effect of stacking direction and raster angle on the fracture properties of Onyx 3D printed components: a mesoscale analysis", 2023, TAFMEC. https://doi.org/10.1016/j.tafmec.2023.104228»

3D printing is gaining a huge interest both in industrial and academic environments. Anyway, the materials typically used in 3D printing need a deep study of their mechanical properties. The main aim of the PhD is the study of the mechanical properties of the structures realized with such innovative production technique. In addition, some reinforcement strategies based on optimization techniques are of primary interests, in order to generate a new generation of tougher structures.

Two parts are distinguished in this thesis. The first one is dedicated to the numerical study of the reinforcements strategies in 3D printed structures. The second one is related to the experimental study of the toughening mechanisms achieved by means of 3D printing.

The main aim of my work is to study the toughening mechanisms that can be achieved by means of 3D printing techniques. The first part was focused on the numerical assessment of these mechanisms, modelling the structures printed in 3D both using one or two materials. The second part is more experimental: we wanted to understand and see what was behind the toughening mechanisms achieved in by using 3D printing.

Conventional 3D printing uses thermoplastic filaments and powder made of ABS, PLA. The main drawback of the use of these materials are the mechanical properties, insufficient for many applications. To improve their performance, short fibers and platelets are added during the extrusion process, not achieving the ones of traditional composites, anyway. Continuous fiber 3D printing integrates, in the polymeric matrix, long fibers such as carbon fiber, fiberglass and Kevlar during the extrusion process, allowing the components printed in such way to achieve mechanical properties very close to the ones of their classical counterpart.

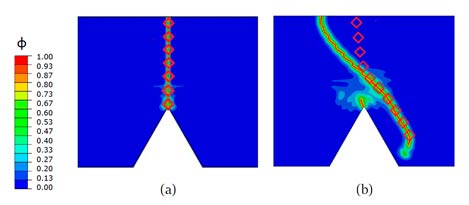

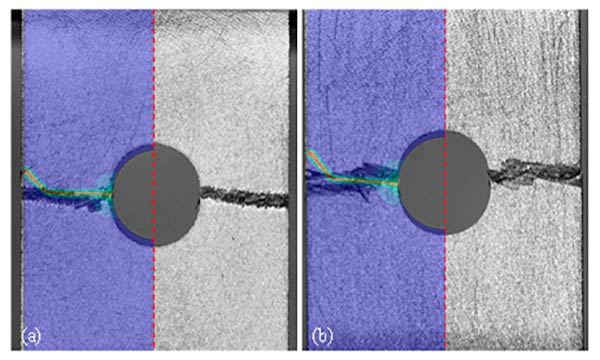

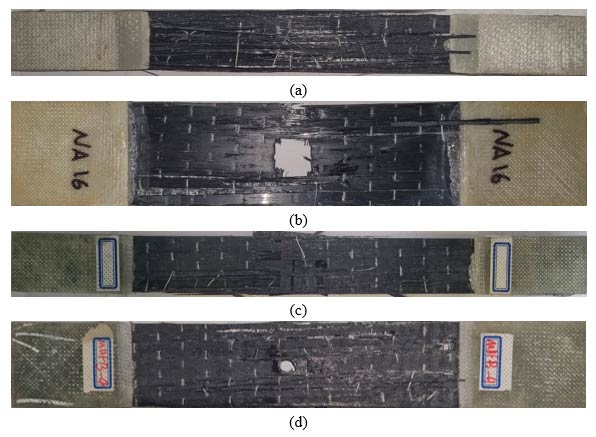

Of fundamental interest is to understand, first of all, whether the phase field tool is able to catch the crack deflection typical of the long fiber reinforced specimens. This was proved by means of a first study where polymeric material and long fibers are modelled as different materials. The study was extended to typical specimens of the mechanical and aeronautical world, like notched and holed tension specimens, see Figure 1.

Figure 1 Phase field simulation of the fracture process for: a) component without reinforcement, b) component with reinforcement.

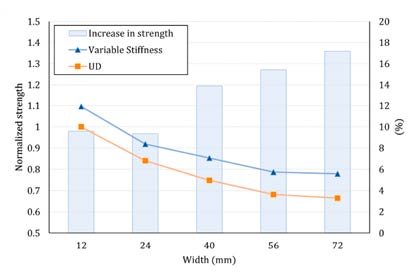

The second part is focused on the improvement of the mechanical performance of 3D printed specimens by means of result driven optimization techniques, see Figure 2. The possibility to shape the reinforcement pattern in the 3D printed components allows an ad-hoc reinforcement, able to increase their mechanical resistance, given the loads they are supposed to endure. The concept has been applied to tension, shear and bending scenarios, demonstrating the efficiency of such procedure in many scenarios.

Figure 2 Improvement of strength for Open Hole Tension specimens by means of a tailored fibre deposition.

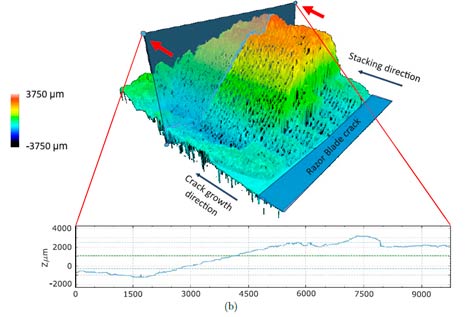

The third part is focused on the experimental investigation of the toughening mechanisms, see Figure 3 and 4. Bending specimens were printed with different configurations of stacking directions and raster angles to check their influence on the mechanical properties of the coupons. After a deep analysis of the fracture surfaces by means of a digital microscope, the best combination of printing parameters to ensure enhanced mechanical properties was found.

All the evidence, both numerical and experimental, could contribute to a larger adoption of the 3D printing technology both in the academic and industrial environment.

Figure 3 Printing configurations studied

Figure 4 Digital image of one of the fracture surfaces.

Date: Defended on 22/03/2024

Link to Open Access Repository: https://idus.us.es/handle/11441/158904»

Presentation: ESR02_Sangaletti_Simone»

All the developments I have made they can be applied in 3D printed materials for space applications.

Sara Jiménez Alfaro

"J’ai appris que la voie du progrès n’était ni rapide ni facile" - Marie Curie

ESR03: Fracture analysis of advanced layered ceramics. See details»

Hello, my name is Sara, I am from Seville (Spain). I studied the Bachelor of Aerospace Engineering and then the Master in aeronautical engineering. I am now finishing my PhD at Sorbonne Université, in the Institut Jean Le Rond d'Alembert. I am ESR3 in NewFrac.

A secret about me? I am very talkative!

University of Seville // Duration: 6 months (June - September 2021, September-October 2022)

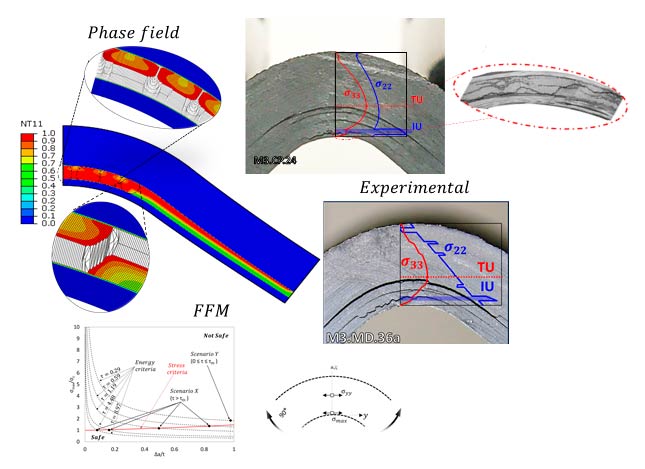

At University of Seville I studied the Phase Field model, one of the two mechanical frameworks that are studied in the network to predict fracture mechanics. The main objective of this secondment was to apply the phase field model at different scales, comparing the results obtained with the ones analysed by the Coupled Criterion (in the framework of Finite Fracture Mechanics).

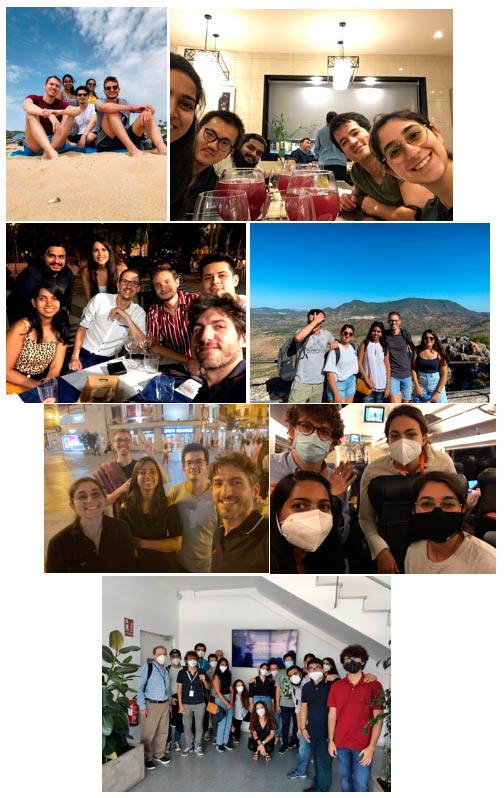

From my personal point of view, the secondment in Seville was an amazing experience. I had the opportunity to meet other PhD students from the network: Karthic (ESR1) , Simone (ESR2), Anatoli (ESR4), Zeng (ESR9), Sindhu (ESR11) and Juan (ESR12). Together with other PhD students in Seville, we made lots of trips together and we become close friends!

Safran // Duration 4 months (March-June 2023)

During this industrial secondment I have applied all the developments I have made during my PhD thesis. We have studied short fibres CMC (ceramic matrix composites), an advanced structure of ceramic material that is now under study by the company. I had the opportunity to live an amazing experience there, meeting other colleagues in the mechanical department. The most important thing I learnt is how to visualize an academic work to be applied in the industry, which I think is a key piece in the development of a project.

- NewFrac Conference – New Computational Strategies for Fracture, held in Porto, Portugal from 07th to 10th May, 2024

- EUROMECH COLLOQUIUM 635 - Finite Fracture Mechanics held in Lyon, France, from 12th to 14th September, 2023. Awarded by the “Best PhD Presentation”

- CFRAC 2023 - Seventh International Conference on Computational Modelling of Fracture and Failure of Materials and Structures, held in Prague, Czech Republic, from 21st to 23rd June, 2023.

- ICF15 - 15th International Conference on Fracture, held in Atlanta, Georgia, USA, from 9th to 19th June, 2023

- NewFrac & TC16 Joint Workshop – “Reaching Out”, held in Torino, Italy, from 17th to 20th January, 2023

- ESMC2022 – 11th European Solid Mechanics Conference, held in Galway, Ireland, from 4th to 8th July, 2022

- ECF23 - European Conference and Summer School on Fracture 2022 held in Funchal, Madeira, Portugal, from 25th June 2022 to 2nd July 2022

- NewFrac Workshop 2 – “Expanding Horizons”, held in Lucca, Italy, from 09th to 12th May, 2022

- IBCSI2022 – 5th Iberian Conference on Structural Integrity, held in Coimbra, Portugal, from 30th March to 1st April, 2022

- NewFrac Workshop 1 – “New Strategies in Computational Fracture Mechanics”, held in Seville, Spain, from 1st to 8th October, 2021

Dissemination

I was also invited to give a seminar at the University of Carlos III, where I could talk about my PhD thesis, see the link below: https://www.youtube.com/watch?v=YfXWCmIoj0g»

I have also taken part in the European Researchers Night during 3 years, an amazing experience that I really enjoyed.

- Baranova, S., Mogilevskaya, S. G., Mantič, V., & Jiménez-Alfaro, S. (2020). Analysis of the antiplane problem with an embedded zero thickness layer described by the Gurtin-Murdoch model. Journal of Elasticity, 140, 171-195. Analysis of the Antiplane Problem with an Embedded Zero Thickness Layer Described by the Gurtin-Murdoch Model | Journal of Elasticity (springer.com)»

- Jiménez-Alfaro, S., Villalba, V., & Mantič, V. (2020). Singular elastic solutions in corners with spring boundary conditions under anti-plane shear. International Journal of Fracture, 223, 197-220. Singular elastic solutions in corners with spring boundary conditions under anti-plane shear | International Journal of Fracture (springer.com)»

- Jiménez-Alfaro, S., & Leguillon, D. (2021). Finite Fracture Mechanics at the micro-scale. Application to bending tests of micro cantilever beams. Engineering Fracture Mechanics, 258, 108012. https://doi.org/10.1016/j.engfracmech.2021.108012»

- Jiménez-Alfaro, S., & Leguillon, D. (2022). Modelling of glass matrix composites by the Coupled Criterion and the Matched Asymptotics approach. The role of a single platelet. Theoretical and Applied Fracture Mechanics, 122, 103650. https://doi.org/10.1016/j.tafmec.2022.103650»

- Jiménez-Alfaro, S., Reinoso, J., Leguillon, D., & Maurini, C. (2022). Finite Fracture Mechanics from the macro-to the micro-scale. Comparison with the Phase Field model. Procedia Structural Integrity, 42, 553-560. https://doi.org/10.1016/j.prostr.2022.12.070»

- Jiménez-Alfaro, S., & Mantič, V. (2020). FEM Benchmark Problems for Cracks with Spring Boundary Conditions Under Antiplane Shear Loadings. Aerotecnica Missili & Spazio, 99(4), 309-319. FEM Benchmark Problems for Cracks with Spring Boundary Conditions Under Antiplane Shear Loadings | Aerotecnica Missili & Spazio (springer.com)»

- Jiménez-Alfaro, S., & Mantič, V. (2023). Crack tip solution for Mode III cracks in spring interfaces. Engineering Fracture Mechanics, 288, 109293. https://doi.org/10.1016/j.engfracmech.2023.109293»

Ceramic materials are widely used in the industry owing to their countless advantages, such as the resistance to corrosion or oxidation. However, they have a very low fracture toughness, which is related to the spontaneous brittle failure of the component. In this context, the main objective of this thesis is the consistent extension of numerical modelling tools in fracture mechanics for predicting crack nucleation and growth in advanced ceramics, with a special emphasis in the relationship between the micro and macro-scale characteristics within these materials. Two approaches are followed: the Coupled Criterion (CC) within the Finite Fracture Mechanics (FFM) framework and the Phase Field (PF) model for fracture.

Two parts are distinguished in this thesis. The first one is dedicated to the study of ceramics fracture properties at the micro-scale. In the second part we focus on the fracture analysis of brittle materials reinforced by a second constituent in the form of micro-platelets or short fibers, a kind of structure of high technological interest for advanced ceramics.

Ceramic materials are widely used in the industry owing to their countless advantages, such as the resistance to corrosion or oxidation. However, they have a very low fracture toughness, which is related to the spontaneous brittle failure of the component. In this context, the main objective of this thesis is the consistent extension of numerical modelling tools in fracture mechanics for predicting crack nucleation and growth in advanced ceramics, with a special emphasis in the relationship between the micro and macro-scale characteristics within these materials. Two approaches are followed: the Coupled Criterion (CC) within the Finite Fracture Mechanics (FFM) framework and the Phase Field (PF) model for fracture.

An inherent property of materials is an internal length frequently named as the Irwin length, that depends on the fracture properties. At the macro-scale, this length is small compared to the dimensions of the specimen. However, at the micro-scale it is of the same order of magnitude or even larger and can interact with the dimensions of the structure. In my PhD thesis this phenomenon is studied considering two different numerical tools. First, in the framework of FFM, a crack is assumed to jump a given finite length at onset, and the CC estimates that this length is proportional to the internal length of the material. On the other hand, in the PF model for brittle fracture there is a length related to the size of the damaged region, called the phase field length scale, that is also proportional to the internal length of the material.

Moreover, we study the answer brought by both the CC and the PF model when descending the scales from the cm-scale to the μm-scale and even nm-scale. This would help to better describe ceramic materials at the micro-scale, and therefore to enhance the design of advanced ceramics, which is commonly based on changing the micro-structure of classical ceramics to generate new materials with improved mechanical properties. One type of these new structures is deeply studied in my PhD, made of brittle matrices reinforced by short fibers or platelets. They are analyzed using numerical techniques that avoid the controversial conclusions obtained about fracture properties when descending the scales in ceramics.

Thus, we develop a computational tool to study the fracture behaviour of such composites, based on the connection between the micro- and the macro-scale. The aim of this tool is to provide an insight into the changes generated in the crack propagation when it encounters the reinforcing element, estimating the apparent fracture toughness of the composite as a function of design parameters.

To sum up, two parts are distinguished in this thesis. The first one is dedicated to the study of ceramics fracture properties at the micro-scale. In the second part we focus on the fracture analysis of brittle materials reinforced by a second constituent in the form of micro-platelets or short fibers, a kind of structure of high technological interest for advanced ceramics.

Date: Defended on 16/10/2023

Link to Open Access Repository: https://theses.hal.science/tel-04694320v2»

Presentation: ESR03_Jimenez_Sara»

- CLEAN AND SUSTAINABLE MOBILITY»: The design tool I have developed during my PhD thesis has been applied to a material proposed by Safran company to enhance the performance of the engine and therefore to achieve climate neutrality by 2050

- EU SPACE POLICY»: All the developments I have made they can be applied in ceramics materials for space applications.

Anatoli A. Mitrou

"Imagination creates reality"

ESR04: Fracture of LFRP ultra-thin ply laminates in aeronautical applications. See details»

I am a musician at heart and an engineer by trait that really enjoys discovering new things. I have thus far already traveled quite a bit and can understand more languages than I can properly speak (oh well…beware!). I fell in love with flying age 5 and have since enjoyed almost all things aerospace related, with no one topic being my favorite, but would love to at some point work on a project that is completely novel and that will bring light to new knowledge, such as a personal favorite NASA’s Cassini-Huygens mission.

Sevilla // Duration: 6 months (Sept. 2021 - March 2022)

I was at the university of Seville for a total of 6 months starting in the fall of 2021. During that secondment my task was to work on the Phase Field formulation part of my work. It was a good opportunity to work with other ESR’s on a technical level as a couple of them were also there, ESR1, ESR2, ESR3, ESR9, ESR11, ESR12. With ESR2 especially, aka Simone Sangaletti, this sparked a joint venture to work together on a topic that eventually has now led to published work. With these ESRs we drove to some cool places in Andalucia tried food and experienced fun times through which strong friendships occured.

Madrid // Duration: 3 months (Sept. 2022 - Dec. 2022)

As part of FIDAMC in Madrid, a composite testing and manufacturing company, I had a very nice time. I got to interact with the experts in the field there and learn from them. I also got to do part of my testing there with them. It was overall nice to also get to meet and experience another Spanish city.

In total I have attended 9 international conferences and workshops, at which I presented each time the developments of my work during that time.

- NewFrac Conference – New Computational Strategies for Fracture, held in Porto, Portugal from 07th to 10th May, 2024

- COMPOSITES 2023 - 9th ECCOMAS Thematic Conference on the Mechanical Response of Composites, held in Trapani, Italy, from 12th to 14th September, 2023

- ICCM23 – International Conference on Composites Materials, held in Belfast, UK, from 30th July to 04th August, 2023

- CFRAC 2023 - Seventh International Conference on Computational Modelling of Fracture and Failure of Materials and Structures, held in Prague, Czech Republic, from 21st to 23rd June, 2023.

- ICF15 - 15th International Conference on Fracture, held in Atlanta, Georgia, USA, from 9th to 19th June, 2023

- NewFrac & TC16 Joint Workshop – “Reaching Out”, held in Torino, Italy, from 17th to 20th January, 2023

- ECF23 - European Conference and Summer School on Fracture 2022 held in Funchal, Madeira, Portugal, from 25th June 2022 to 2nd July 2022

- NewFrac Workshop 2 – “Expanding Horizons”, held in Lucca, Italy, from 09th to 12th May, 2022

- NewFrac Workshop 1 – “New Strategies in Computational Fracture Mechanics”, held in Seville, Spain, from 1st to 8th October, 2021

Attending these conferences and the extra interaction with experts was incredibly nice. I developed good soft skills and made more than a few nice connections. Additionally, I have attended all the NewFrac workshops, small internal almost conferences, that gave us the opportunity to collectively learn about each other’s work and given the more closed nature of these workshops I was able to develop a close relationship with some professors outside the network as well. Apart from all things professional, the travels attached and experiences and food that I tried during these events is something cherishable.

Dissemination

Moreover, I have taken part in the European Researchers’ Night during 3 years, an amazing opportunity to bring science closer to people who are not involved in the field.

- Modeling fracture of multidirectional thin-ply laminates using an anisotropic phase field formulation at the macro-scale». A Mitrou, A Arteiro, J Reinoso, PP Camanho. International Journal of Solids and Structures 273, 112221 (2023)

- Effect of tailored fiber deposition in 3D printed composites: application of an anisotropic phase field model». S Sangaletti, A Mitrou, IG García, A Arteiro. Theoretical and Applied Fracture Mechanics 127, 104030 (2023)

- Application of Composite Materials to Reduce Mass of Internal and External Exploration Habitat Structures». M Simon, L Carpenter, G Hrinda, A Bergan, J Samareh, A Mitrou. 49th International Conference on Environmental Systems. 2019

My work pertains to developing a tool for the macro-scale level analysis of Multidirectional Thin-ply laminates. The two methods proposed are the use of the Phase Field (PF) method and the coupled Finite Fracture Mechanics (FFM) criterion. The specific problem this was applied to was predicting the off-axis response of a range of lay-ups both concerning strength and fracture path.

Studying how materials used in airplanes break to be able to safely design and use them in new aircraft of the future. In order to use a certain material, you must know how and when it breaks. Thus, engineers like me work on creating methods and the tools to know how each material used on airplanes behaves, how much it can take before failing, to use them with confidence.

Date: Defended on 30/07/2024

Link to Open Access Repository: https://hdl.handle.net/10216/161780»

Presentation: ESR04_Mitrou_Anatoli»

- CLIMATE ACTION: My work is directly linked to the efforts made by the aerospace industry to improve their tools and materials used for more efficient aircraft that will help lead to more sustainable and efficient flight. Part form that my work con novel materials could also be extended to any application this material or these numerical techniques could lead to use of less “scrap” material and thus lead to more sustainable R&D and end products.

Camilla Zolesi

"Beauty is truth, truth beauty,—that is all Ye know on earth, and all ye need to know." from Ode on John Keats

ESR05: Nucleation and propagation of compressive cracks. See details»

I am a Ph.D. student with a deep enthusiasm for theoretical mechanics. My passion extends to both mechanics and sea sports. I am particularly enthusiastic about the untapped research prospects in modeling physical phenomena like and I aspire to make a contribution to this field. What captivates me in the scientific research and the sea is the fact that they both embody a sense of freedom despite the rigor required.

ETH Zürich, Switzerland // Duration: 6 months (Jun 2021 - Sept 2021 & Jun 2022 - Jul 2022), Supervisor: Prof. Laura De Lorenzis

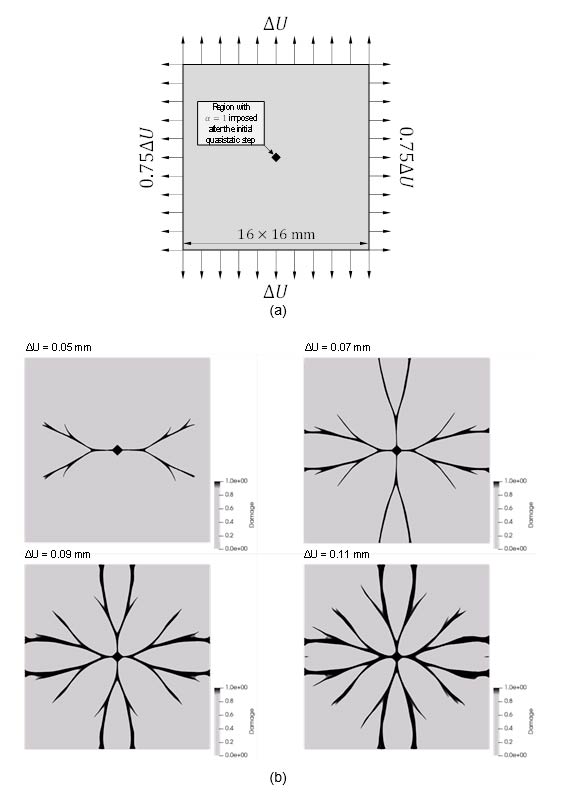

We established a collaboration with ESR10 in order to sort the wealth of literature based on specific criteria pointed out during this preliminary analysis. We define these criteria as the ability to flexibly reproduce multi-axial strength and avoid interpenetration of crack faces, and so we perform a systematic review of some available models. Based on these concepts, we propose numerical benchmarks to evaluate the behavior of solutions in literature. In particular, the proposed tests provide an assessment of a phase field model for both nucleation and propagation.

Renningen, Germany // Duration. 4 months (Mar 2023 - Jun 2023), Supervisor: Dr. Fabian Welshinger.

In order to maximize the benefit of the researcher's secondment period at Bosch, a collaboration was initiated to compare the models developed for quasi-incompressible materials with experimental data on adhesive joints held by Bosch.

- NewFrac Conference – New Computational Strategies for Fracture, held in Porto, Portugal from 07th to 10th May, 2024

- CFRAC 2023 - Seventh International Conference on Computational Modelling of Fracture and Failure of Materials and Structures, held in Prague, Czech Republic, from 21st to 23rd June, 2023.

- 8th GAMM Workshop on Phase-field modeling, held in Zürich, Switzerland, from 6th to 7th February, 2023

- NewFrac & TC16 Joint Workshop – “Reaching Out”, held in Torino, Italy, from 17th to 20th January, 2023

- ECF23 - European Conference and Summer School on Fracture 2022 held in Funchal, Madeira, Portugal, from 25th June 2022 to 2nd July 2022

- CSMA2022 – 15éme Colloque National en Calcul des Structures, held in Giens, France, from 16th to 20th May, 2022

- NewFrac Workshop 2 – “Expanding Horizons”, held in Lucca, Italy, from 09th to 12th May, 2022

- NewFrac Workshop 1 – “New Strategies in Computational Fracture Mechanics”, held in Seville, Spain, from 1st to 8th October, 2021

Dissemination

European Researchers’ Night (organizer), NewFrac & Politecnico di Torino, Italy, (Sept 30, 2022), NewFrac & Universidad de Sevilla, Spain, (Sept 30, 2022 & Sept 24, 2021).

- F. Vicentini, C. Zolesi, P. Carrara, C. Maurini. L. De Lorenzis, On the energy decomposition in variational phase-field models for brittle fracture under multi-axial stress states, submitted to IJF (soon the link to the pre print)

Phase-field (PF) modeling of fracture is gaining popularity in the fracture mechanics community, particularly for its ability to generate cracks with arbitrarily complex geometries and topologies in two and three dimensions without the need for ad hoc criteria. The model first introduced in [1] has a clear connection with Griffith’s propagation criterion via Gamma convergence tools and further results [2] have shown that, in addition to propagation, it can quantitatively predict crack nucleation for mode-I loading. However, the initial model cannot reproduce with flexibility the experimentally measured strengths under multi-axial loads. Moreover, a modification is necessary to avoid the interpenetration of crack surfaces in compression and reflect the physical asymmetry of fracture behavior between tension and compression [3]. The project is inscribed in the study and analysis of these issues and limitations to broaden the applicability of PF model to multi-axial loads.

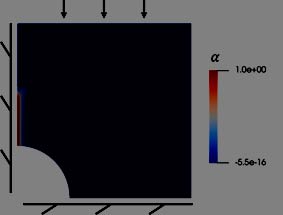

Fig. 1: Plate with hole test using the new model. A parameter is calibrated to obtain a crack parallel to the loading direction. The original phase-field model fails in reproducing such experimentally observable crack direction.

Phase-field modeling of fractures is a technique used to understand how materials break apart. It's becoming quite popular because it allows us to predict complex crack patterns in 2D and 3D without using additional rules.

But here's the catch: this model isn't great at explaining how materials break under different kinds of forces, like when you push or twist them. Our project is all about studying these issues and trying to make this model more useful for a wider range of situations where things break in different ways.

Date: Defended on 14/12/2023

Link to Open Access Repository: https://theses.hal.science/tel-05045250»

Presentation: ESR05_Zolesi_Camilla»

This work contributes to research and innovation by expanding our understanding, introducing novel solutions, addressing challenges and fostering collaboration, more specifically:

- Clean energy»: In order to alleviate the human impact on climate change resulting from the release of greenhouse gases, the EU is actively promoting the transition to clean energies. However, the success of this initiative hinges on simultaneously guaranteeing energy security within the EU. In this context, the current investigation aims to shed light on the crashworthiness behavior and operational life assessment of pivotal facilities involved in the production and/or distribution of renewable energy

- Clean and sustainable mobility»: With the goal of achieving a climate-neutral EU, it is crucial to develop and implement efficient and clean transportation methods. This is essential for sustaining the mobility of both people and goods while ensuring environmentally responsible economic competitiveness. To achieve this objective, a comprehensive understanding of material failure across various conditions becomes crucial. Such knowledge enables the utilization of lighter structures without compromising safety, ultimately leading to increased efficiency. Our specific investigation is dedicated to unraveling the complexities of fractures under multi-axial stress states condition.

- EU Industrial Policy»: We align ourselves with the EU's industrial policy by promoting innovation and technological progress. Our efforts in developing innovative methods for materials analysis and design actively contribute to enhancing the competitiveness and sustainability of industries within the EU.

- Energy Union»: While our primary emphasis is on modeling materials behavior, our research indirectly aligns with the objectives of the Energy Union. Through the promotion of energy-efficient materials and manufacturing processes, we actively contribute to the establishment of a secure, sustainable, and affordable energy supply.

- Advancement of Knowledge: Through our research and innovation efforts, we have gained fresh insights into the challenge of multi-axial load fractures. These findings possess a theoretical universality, making them applicable to various brittle materials. The investigation significantly advances the existing body of knowledge in its respective field. It explores previously uncharted territory, providing new insights, methodologies and solutions that were not previously available.

- International and interdisciplinary collaboration: The work involves collaboration between different countries and sectors.

Ángela Fajardo

Everything cracks for a reason, I mean happens.

ESR06: Multiscale modeling of fracture processes in injection molded SFRPs. See details»

My name is Angela and I come from Sevilla, where I graduated in Industrial Technologies Engineering. I specialized in material mechanics. After my degree, I got the chance to participate in an Erasmus Mundus Joint Master Degree, issued by AIX Marseille University, Tor Vergata Roma and Politechnical University of Wroclaw. The academic program was focusing on nanoengineering and I got a different perspective about materials and their behaviour. My versatile background led me to this PhD position within NewFrac. I am currently working in Robert Bosch campus for research and advance engineering. Though set in Stuttgart, I am enrolled in ETH Zürich. My doctoral research focuses on the fracture behaviour of short fiber reinforced polymers.

ETH Zürich, Switzerland // Duration: 2 months (Sept - Oct)

My initial secondment has been divided into two phases to maximize the benefits derived from the academic environment and university courses. Thus far, I have already dedicated four months to my host institution, ETH Zürich. The remaining two months of this secondment are scheduled from September 1st to October 31st.

Engaging with close research collaborators has consistently proven to be an enriching experience. In my case, I am genuinely thankful for the opportunity to immerse myself in research within a purely academic setting. Additionally, maintaining frequent communication with my supervisors, both from Bosch and the university, has provided me with valuable guidance and insights.

Throughout the initial phase of my stay, I predominantly concentrated on the modeling aspect. This period allowed me to engage in constructive discussions, exchange ideas, and benefit from valuable insights shared among my colleagues within the research group. The secondment's structure has encouraged me to think out of the box, fostering an environment that promotes innovative thinking.

An integral part of this experience has been the interdisciplinary collaboration that naturally occurs in such a vibrant academic atmosphere. Interacting with professionals from various fields has broadened my perspective and enhanced my problem-solving skills. I have also had the opportunity to become acquainted with projects that, although distant from my primary research topic, have contributed to the incorporation of new perspectives.

As I reflect on my journey thus far, I am looking forward to continuing the adventure of secondments, both at ETH Zürich and Paris Sorbonne. I am prepared to seize every opportunity to learn and grow, and I am excited to make the most of my experiences in these esteemed academic institutions.

Incorporating these aspects has made my secondment not only academically rewarding but also a well- rounded experience that has fueled my personal and professional growth.

Until this point in my PhD journey, I've had the privilege of participating in a diverse range of events that have significantly enriched my perspective, providing continuous inspiration, motivation, and encouragement. I've categorized these events into three distinct areas: knowledge acquisition, sharing scientific insights, and connecting with the wider public.

When it comes to acquiring knowledge, I've taken part in pivotal events such as the NewFrac PRO and LEAD schools. These experiences not only deepened my understanding but also fostered a sense of unity among ITN members, encouraging meaningful face-to-face discussions that go beyond virtual meetings. The NewFrac workshops played a crucial role in refining my ability to present and communicate our research effectively to a scientific audience. This was further amplified during my participation in a two-day Digimat course event within my industry department. A recent standout experience was the CISM course on Variational Methods, which unfolded in a hub known for its contributions to computational mechanics.

In the context of scientific dissemination, I've had the privilege of attending numerous international conferences. The foundations for presenting our work were solidified during the Newfrac workshops, where I gained valuable experience in presenting to both ITN colleagues and external researchers. Expanding on this foundation, I presented our research at the ECF23 in June 2022, while Dr. Fabian Welschinger represented our work at ICF15 in June 2023. Another remarkable event was our presentation at CFRAC, a thematic ECCOMAS conference held in Prague in June 2023. My journey has also encompassed active engagement in events like the GAMM workshop in the phase field, the Material Strength & Durability Symposium 2023, and the PhD colloquium at the Robert Bosch GmbH Center for Research and Advanced Engineering.

Furthermore, I'm dedicated to making science accessible to the public, as evident through my involvement in activities such as the European Researcher's Night in Turin in September 2022. This experience not only allowed us to share our work but also nurtured creativity as we worked to make complex concepts comprehensible. Engaging with individuals from diverse backgrounds, including children, offered rewarding interactions. These exchanges underscored the importance of effective science communication in sparking curiosity and fostering interest.

Looking ahead, I'm eagerly anticipating my participation in upcoming events such as COMPLAS and COMPOSITES23, both thematic ECCOMAS conferences scheduled for September 2023. These gatherings hold the potential to expand our contributions and infuse our journey with innovative ideas from various disciplines.

None for the moment.

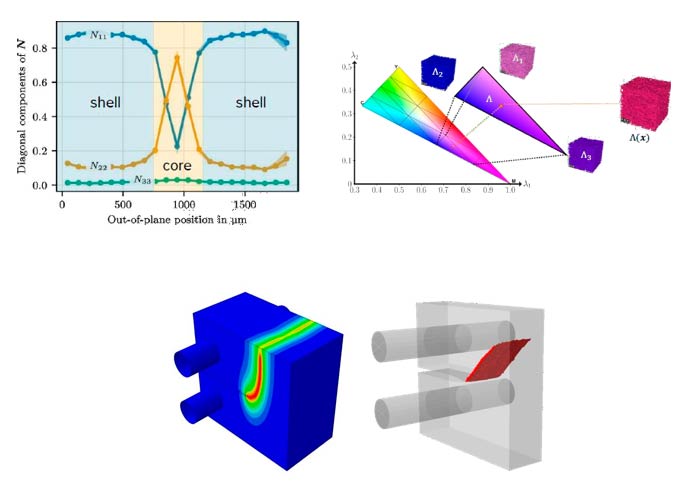

Understanding and modeling the fracture mechanical behavior of short glass fiber reinforced polymers (SFRPs) presents a tough challenge. This difficulty arises from the pronounced heterogeneity induced by the manufacturing process, resulting in a close coupling of the material's microstructure with its effective response at the component scale. SFRP parts, typically produced via injection molding, exhibit locally varying microstructural configurations. These variations affects the fiber orientation, volume content or length distribution, which collectively add complexity to the modelling task.

In order to address this intricacy stemming from microstructural diversity and its influence on macroscopic behavior, we employ a multiscale approach. This approach extends the well-established isotropic phase field models of brittle fracture into the anisotropic domain, introducing a fiber orientation interpolation. To construct the necessary database, we derive anisotropic elastic coefficients from previously conducted micromechanical simulations based on realistic microstructures. The calculations are efficiently performed using FeelMath FFT solver.

At the simulation level, the local microstructure must be known in order to access the database: microstructural information stemming from either X-ray micro computed tomography [3] or from injection moulding process simulation is mapped into the Abaqus mesh prior the execution of the macroscopic simulation.

The performance of this simulation methodology is showcased through numerous numerical analyses, shedding light on both the predictive capabilities and limitations of the proposed method. In this context, we introduce an innovative approach that combines offline training of a database with a fiber interpolation concept, enabling us to account for the material's inherent heterogeneity. This approach seamlessly integrates into the simulation workflow for SFRPs, spanning from the manufacturing process to the mechanical fracture analysis of the final structure. Moreover, we quantify the limitations inherent to our approach, stemming from the underlying assumptions, and identify areas for further development.

I have been engaged in the study of a specialized material known as short glass fiber reinforced polymers (SFRPs), which are used to enhance the strength and durability of various products, including automotive components and electronic devices. These materials, however, pose a unique challenge due to their inherent heterogeneity, stemming from the manufacturing process. This results in a complex interplay between the material's microstructure and its overall performance on a larger scale.

To address this complexity, my research takes a multiscale approach to understand how SFRPs fracture. Typically, these materials are created through injection molding, leading to variations in local microstructures, such as differences in fiber orientations, fiber content, and fiber lengths. These variations make modelling how and when the material breaks a challenging task.

In order to account for this microstructural diversity and its impact on how the material behaves, I've been working on an anisotropic fracture model. This extension uses a concept called 'fiber orientation interpolation' to capture the material's anisotropic behavior.

To build a comprehensive database for my research, I've obtained anisotropic elastic coefficients from detailed micromechanical simulations performed on realistic microstructures. These simulations are conducted efficiently using a specialized microscopic solver called FeelMath.

At the simulation level, it's essential to have detailed knowledge of the local microstructure to effectively use the database. Microstructural data, obtained through methods such as X-ray micro- computed tomography or simulations of the injection molding process, is integrated into the simulation mesh before running the macroscopic analysis.

My research demonstrates the effectiveness of this simulation method through numerous numerical analyses. It provides insights into the quality of predictions and highlights the limitations of the proposed approach.

In conclusion, my work introduces an innovative approach that combines offline database training with fiber interpolation concepts to account for material heterogeneity. This approach seamlessly integrates into the entire simulation process for SFRPs, from manufacturing to structural mechanical fracture analysis. By quantifying the limitations arising from underlying assumptions, we can identify areas for further development.

Expected Date: Before October 2025

Our current research, centered on understanding and modeling the fracture mechanical behavior of short glass fiber reinforced polymers (SFRPs), is certainly related with the European Green Deal and other EU policies that prioritize sustainability, innovation, and environmental protection. We firmly believe that our work echoes the following key EU policies:

- European Green Deal»: This vast framework, which advocates resource efficiency and a circular economy, finds a resonance in our research. By optimizing SFRPs, we contribute to the efficient use of materials in manufacturing, aligning with the Green Deal's objectives to minimize waste and maximize resource

- Clean Energy»: Our research indirectly supports the EU's clean energy goals by enhancing the efficiency of SFRP manufacturing and materials. This improvement lends itself to cleaner energy production and utilization, fitting well within the broader EU vision for cleaner energy technologies.

- Clean and Sustainable Mobility»: The potential impact of our research on clean and sustainable mobility is By enhancing the performance and longevity of materials used in transportation, such as engine components, we play a part in making vehicles more energy-efficient and environmentally friendly. In particular, from the application point of view, SFRP are highly demanded in electromobility parts. Therefore, our research is indirectly promoting the sustainable mobility success.

- EU Industrial Policy»: We align with the EU's industrial policy by fostering innovation and technological Our development of novel methods for materials analysis and design contributes to the competitiveness and sustainability of EU industries.

- Energy Union»: Although our primary focus is on materials, our research indirectly supports the objectives of the Energy Union. By promoting more energy-efficient materials and manufacturing processes, we contribute to a secure, sustainable, and affordable energy

- European Research Area»: Our dedication to research and innovation positively aligns with the European Research Area's aim to create a unified and competitive European research

- Horizon Europe»: Our research has the potential to synergize with the Horizon Europe program, promoting scientific excellence and addressing global Our innovative methods and multiscale approach line up with the program's goals, fostering research collaborations and technological advancements.

- EU Cooperation on Security and Defense»: While not a direct link, the durability and performance enhancements stemming from our research indirectly bolster EU cooperation on security and Materials used in critical applications, such as aerospace and defense, benefit from improvements in strength and reliability.

In essence, our research is in concordance with various EU policies, including the European Green Deal. It underscores the broader social and economic impact of our work within the context of EU policy objectives, illustrating the potential for science and innovation to play a vital role in advancing sustainability and environmental responsibility.

Amir Mohammad Mirzaei

In pursuit of knowledge, advancing the frontiers of fatigue and fracture mechanics to engineer more resilient and sustainable materials

ESR07: Debonding of the reinforcement in LFRP externally strengthened curved beams. See details»

I am Amir Mohammad Mirzaei, a Marie Skłodowska-Curie PhD candidate in Fatigue and Fracture Mechanics at Politecnico di Torino, Italy. My research, focuses on Finite Fracture Mechanics and Phase Field models for predicting fatigue, fracture, and debonding in composite structures. I hold an M.Sc in Solid Mechanics from Iran University of Science and Technology and a B.Sc in Mechanical Engineering from the University of Tabriz. My academic journey has been marked by several honors and awards, including a Marie Skłodowska-Curie scholarship and being named the Distinguished Researcher of the Year during my Master's. I have an extensive list of publications in reputable journals and have presented my work at international conferences. In addition to my research, I have teaching and supervising experience and have served as a reviewer for scientific journals. I have also had the privilege of being a visiting scholar at ETH Zurich and FIDAMC company, for one year. My technical skills include fatigue and fracture analyses using various methods and mathematical modeling, supported by proficiency in software like ABAQUS and programming languages such as Mathematica and MATLAB.

ETH Zürich, Switzerland // Duration: 6 months (Sep 2021 - Feb 2022)

I had the opportunity to undertake a six-month secondment at ETH Zurich, one of the world's leading universities in technology and sciences. My focus during this period was on phase field and fatigue, and I had the privilege of collaborating with some of the leading teams in the field. This experience was instrumental in deepening my understanding of the theoretical frameworks and computational methods related to phase field modeling. The collaborative nature of the work at ETH Zurich enriched my research perspective and allowed me to integrate cutting-edge methodologies into my own projects. Overall, the secondment at ETH Zurich was a transformative experience that significantly contributed to both my professional development and the advancement of my research.

Rooftop of ETH.

FIDAMC Getafe, Madrid // Duration 4 months (May 2023 - Aug 2023)

I completed an industrial secondment at FIDAMC (The Composites Research, Development and Application Centre) in Getafe, Madrid. FIDAMC is a leading research center specializing in the industrial application of composite materials. The experience was nice; The secondment not only broadened my academic perspective but also provided a practical lens through which to view the impact of research on critical industrial sectors like aerospace. Overall, the secondment was a fulfilling experience that bridged the gap between academic research and industrial application.

Entrance of FIDAMC.

- NewFrac Conference – New Computational Strategies for Fracture, held in Porto, Portugal from 07th to 10th May, 2024

- CFRAC 2023 - Seventh International Conference on Computational Modelling of Fracture and Failure of Materials and Structures, held in Prague, Czech Republic, from 21st to 23rd June, 2023.

- IGF27 - 27th International Conference on Fracture and Structural Integrity, held in Rome, Italy, from 22nd to 24th February, 2023

- NewFrac & TC16 Joint Workshop – “Reaching Out”, held in Torino, Italy, from 17th to 20th January, 2023

- ECF23 - European Conference and Summer School on Fracture 2022 held in Funchal, Madeira, Portugal, from 25th June 2022 to 2nd July, 2022

- NewFrac Workshop 2 – “Expanding Horizons”, held in Lucca, Italy, from 09th to 12th May, 2022

- NewFrac Workshop 1 – “New Strategies in Computational Fracture Mechanics”, held in Seville, Spain, from 1st to 8th October, 2021

- IGF26 - 26th International Conference on Fracture and Structural Integrity, held in Torino, Italy, from 26th to 28th May, 2021

Dissemination

Moreover, I have taken part in the European Researchers’ Night during 2 years, an amazing opportunity to bring science closer to people who are not involved in the field.

IGF27, Rome.

- M. Mirzaei✉, A. H. Mirzaei, A. Sapora, M. M. Shokrieh, P. Cornetti (2023)

“Fatigue life assessment of notched laminated composites: Experiments and modelling by finite fracture mechanics” Composites Science and Technology, https://doi.org/10.1016/j.compscitech.2023.110376»

- Bahrami✉, M. R. Ayatollahi, A.H. Gholizadeh, A. M. Mirzaei, M.R. Mehraban (2023)

“Mixed mode brittle fracture prediction in cracks under frictional condition” Theoretical and Applied Fracture Mechanics, https://doi.org/10.1016/j.tafmec.2023.104211»

- M. Mirzaei✉ (2023)

“Stress, Strain, or Energy: Which One is the Superior Parameter to Estimate Fatigue Life of Notched Components? An Answer by A Novel Machine Learning-Based Approach”. Arxiv, https://doi.org/10.48550/arXiv.2310.11859»

- M. Mirzaei✉, P. Cornetti, A. Sapora (2023)

Asymptotic stress field for the blunt and sharp notches in bi-material media under mode III loading”. Journal of Applied Mechanics, ASME, https://doi.org/10.1115/1.4064323»

- M. Mirzaei✉, P. Cornetti, A. Sapora (2023)

“A novel Finite Fracture Mechanics approach to assess the lifetime of notched components”. International Journal of Fatigue, https://doi.org/10.1016/j.ijfatigue.2023.107659»

- M. Mirzaei✉, B. Bahrami, M. R. Ayatollahi (2022)

“Asymptotic stress field around the blunt and sharp notches in bimaterial media under mixed mode I/II loading”. Applied Mathematical Modelling, https://doi.org/10.1016/j.apm.2022.04.017»

- M. Mirzaei✉, M. Corrado, A. Sapora, P. Cornetti (2022)

“Analytical Modeling of Debonding Mechanism for Long and Short Bond Lengths in Direct Shear Tests Accounting for Residual Strength”. Materials, https://doi.org/10.3390/ma14216690»

- M. Mirzaei, M. R. Ayatollahi✉, B. Bahrami, F. Berto (2021)

“A new unified asymptotic stress field solution for blunt and sharp notches subjected to mixed mode loading”. International Journal of Mechanical Sciences, https://doi.org/10.1016/j.ijmecsci.2020.106176»

- Bahrami, M. R. Ayatollahi✉, A. M. Mirzaei, M.Y. Yahya (2021)

“Support type influence on rock fracture toughness measurement using semi-circular bending specimen”. Rock Mechanics and Rock Engineering, https://doi.org/10.1007/s00603-019-02023-z»

- M. Mirzaei, M. R. Ayatollahi✉, B. Bahrami, F. Berto (2020)

“Elastic stress analysis of blunt V-notches under mixed mode loading by considering higher order terms”. Applied Mathematical Modelling, https://doi.org/10.1016/j.apm.2019.09.049»

- Bagheri, M. Ayatollahi✉, A. M. Mirzaei, M. M. Monfared (2019)

“Multiple defects in a piezoelectric half-plane under electro-elastic in-plane loadings”, Theoretical and Applied Fracture Mechanics, https://doi.org/10.1016/j.tafmec.2019.102316»

- Bahrami, M. R. Ayatollahi✉, A. M. Mirzaei, F. Berto (2019)

“Improved stress and displacement fields around V-notches with end holes” Engineering Fracture Mechanics, https://doi.org/10.1016/j.engfracmech.2019.106539»

- R. Ayatollahi✉, B. Bahrami, A. M. Mirzaei, M.Y. Yahya (2019)

“Effects of support friction on mode I stress intensity factor and fracture toughness in SENB testing” Theoretical and Applied Fracture Mechanics, https://doi.org/10.1016/j.tafmec.2019.102288»https://doi.org/10.1016/j.tafmec.2019.102288»

- M. Mirzaei, M. R. Ayatollahi✉, B. Bahrami (2019)

“Asymptotic stress field and the coefficients of singular and higher order terms for V-notches with end holes under mixed-mode loading” International Journal of Solids and Structures, https://doi.org/10.1016/j.ijsolstr.2019.05.011»

- Bahrami, M. R. Ayatollahi✉, A. M. Mirzaei (2019)

“Analysis of stresses and displacements in the vicinity of blunt V-notches by considering higher order terms” Fatigue & Fracture of Engineering Materials & Structures, https://doi.org/10.1111/ffe.13016»

- Bagheri✉, A. M. Mirzaei (2017)

“Fracture Analysis in an Imperfect FGM Orthotropic Strip Bonded between Two Magneto-Electro-Elastic Layers” Iranian Journal of Science and Technology: Transactions of Mechanical Engineering, https://doi.org/10.1007/s40997-017-0129-6»

Fatigue-induced failure represents a significant mode of structural collapse and has been the central focus of extensive research for several decades. This mode of failure arises from damage caused by repeated cycles of loading and unloading. In light of the long-term and potentially catastrophic consequences of fatigue, it is paramount to understand this phenomenon and accurately predict its occurrence in composite structures, as this understanding directly impacts their reliability and lifespan.

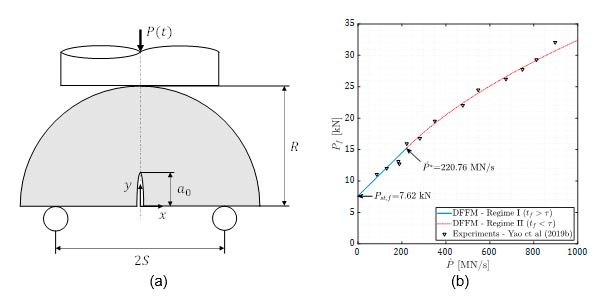

My project aims to delve deeply into fatigue, fracture, and debonding within composite structures, with the goal of enhancing our understanding of these areas. Specifically, I focus on the application of the Coupled Criterion Finite Fracture Mechanics (CCFFM), aiming to broaden its usage into fatigue loading situations. The CCFFM has already shown considerable accuracy in predicting failure in notched components and analyzing debonding in composites, thus extending its application to fatigue loading scenarios is a compelling prospect.

Simultaneously, this project intends to explore the Phase Field (PF) models in numerical structural analysis, especially in fatigue loading contexts. Considering the dearth of research validating PF models against experimental data, this study seeks to bridge this gap, affirming the efficacy of PF models in predicting fatigue-related damage in structures. By incorporating these advanced mechanics and modeling techniques, the project aspires to foster the development of more resilient, safer, and fatigue-resistant composite and advanced structures for the future.

Failed composite specimens due to fatigue. (a) plain, (b) cracked (c) holed with r = 2.1 mm, (d) holed with r = 3.25 mm.

Date: Defended on 12/06/2024

Link to Open Access Repository: https://iris.polito.it/handle/11583/2989635»

Presentation: ESR07_Mirzaei_Amir_Mohammad»

European Green Deal». My research on "Finite Fracture Mechanics and Phase Field Models for Predicting Fatigue, Fracture and Debonding in Composite Structures" contributes to the European Green Deal by offering valuable insights into the durability and longevity of materials used in eco-friendly technologies. By accurately predicting fatigue, fracture, and debonding, I aim to facilitate the development of more sustainable and efficient materials, which can ultimately reduce waste and energy consumption.

Clean Energy». The predictive models I am developing are particularly relevant to the clean energy sector. They can be instrumental in the design and maintenance of renewable energy infrastructure, such as solar panels and wind turbines. My work aims to enhance the understanding of material behavior under various conditions, leading to more efficient and reliable energy systems.

EU Industrial Policy». My research has the potential to significantly impact the EU's industrial policy by fostering innovation in material science. Industries can use the predictive models I am developing to either create new materials or optimize existing ones, thereby enhancing the global competitiveness of European industries.

Energy Union». My work contributes to the objectives of the Energy Union by aiding in the development of more efficient and durable materials. This aligns with the Energy Union's goals of secure, sustainable, competitive, and affordable energy for all EU citizens.

Horizon Europe». My research is closely aligned with the goals of Horizon Europe, which aims for impactful investment in innovation and research. The methodologies and findings from my work can be integrated into various Horizon Europe projects, especially those focusing on material science, engineering, and sustainability.

European Research Area». As a Marie-Curie PhD student, I am already contributing to the European Research Area by enhancing scientific capabilities within the EU. My specialized focus on fracture mechanics and phase field models can serve as a valuable asset for collaborative research initiatives across member states.

By aligning the outcomes of my research with these key EU policies, I am not only advancing scientific knowledge but also addressing some of the European Union's most pressing challenges. My work has the potential to influence policy decisions and guide future research and industrial practices within the EU.

Maxime Levy

“Those who fall in love with a problem are the ones who invent a solution for it”. (Tel Aviv University)

ESR08: Fracture in biological anisotropic hard tissues (human bones). See details»

I am currently pursuing a Ph.D. at Tel Aviv University as a member of the NewFrac training network working on human bone fracture. I grew up in France and obtained my Master's degree in computational mechanics through a dual-degree program at Sorbonne University and Sapienza University of Rome. My interests lie in both science and engineering, as well as traveling to explore different cultures and languages. It was with great motivation and enthusiasm that I applied for the NewFrac position, which remains with me to this day.

Sorbonne University, Paris, France // Duration: 2 months (October 2021 - December 1, 2021)

During this period, I collaborated with Camilla Zolesi and Prof. Corrado Maurini on the utilization of the FEniCSx computational tool to implement the phase-field method for studying human bone fractures.

ETH, Zürich, Switzerland // Duration: 2 months (December 2021 - February 2022)

During this period, I collaborated with Francesco Vicentini and Prof. Laura De Lorenzis on the numerical implementation and verification of the phase-field method applied to heterogeneous materials, utilizing analytical solutions.

Robert Bosch GmbH, Renningen, Germany // Duration: 4 months (March 2023 - July 2023)

As a visiting student, I learned how to use Simpleware software to segment microstructures following a micro CT scan of composites. I applied this to segment bone microstructure and extract micro-scale properties.

- NewFrac Conference – New Computational Strategies for Fracture, held in Porto, Portugal from 07th to 10th May, 2024

- ICF15 - 15th International Conference on Fracture, held in Atlanta, Georgia, USA, from 9th to 19th June, 2023

- 8th GAMM Workshop on Phase-field modeling, held in Zürich, Switzerland, from 6th to 7th February, 2023

- NewFrac & TC16 Joint Workshop – “Reaching Out”, held in Torino, Italy, from 17th to 20th January, 2023

- ISCM-50, 50th Israel Symposium on Computational Mechanics, held in Tel Aviv, Israel, the 27th, October, 2022).

- ECF23 - European Conference and Summer School on Fracture 2022 held in Funchal, Madeira, Portugal, from 25th June 2022 to 2nd July 2022

- NewFrac Workshop 2 – “Expanding Horizons”, held in Lucca, Italy, from 09th to 12th May, 2022

- NewFrac Workshop 1 – “New Strategies in Computational Fracture Mechanics”, held in Seville, Spain, from 1st to 8th October, 2021

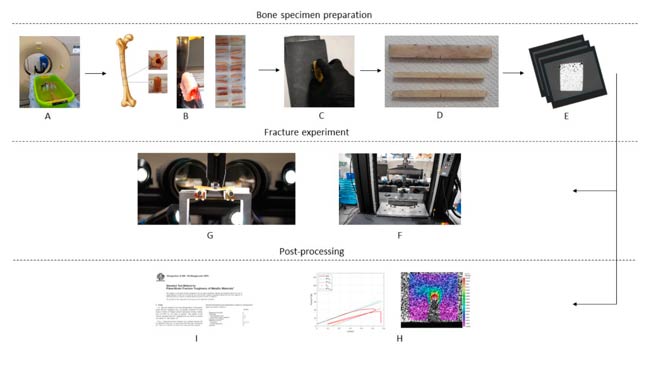

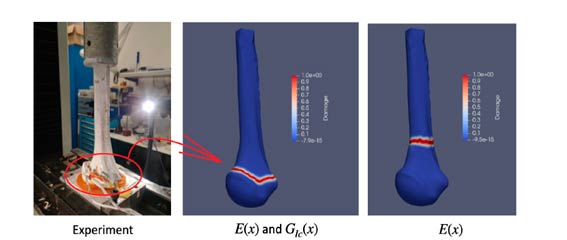

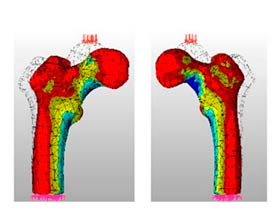

Bone fracture prediction through CT-based Finite Element Analysis (FEA), based on the maximum principal strain criterion, can predict the initiation load of fractures with 80% accuracy, which represents a conservative estimate. However, this method cannot accurately predict the crack path, which is also essential for clinical applications such as preventive surgery.

Phase Field Models (PFMs) hold promise for improving bone fracture predictions, but their accuracy is greatly influenced by the heterogeneous nature of material properties. To enhance our ability to predict fracture initiation and crack paths in human long bones using PFMs, we have employed numerical-experimental methods to determine the material properties of bone tissue. These properties will be integrated with CT-based FEA.

For our experiments, we utilized human fresh frozen femurs, which were CT-scanned to obtain bone density information along the femur. Subsequently, these femurs were sliced to create three-point bending specimens with inserted crack-like defects. Micro-CT scans were performed on these specimens before they were subjected to loading until fracture occurred.

Figure 1: Experimental flowchart to determine bone fracture toughness.

Due to the high heterogeneity of the specimens and their inherent imprecision, Finite Element methods were applied, along with measurements obtained through Digital Image Correlation techniques. As no specific standards exist for determining bone fracture toughness, we have adopted standards commonly used for metals and concrete. Currently, we are conducting additional experiments to more accurately determine the material properties of bone from CT scans.

In parallel, we have implemented the phase-field method for bone fracture and successfully predicted crack locations. Additionally, we have developed an efficient and accurate numerical scheme for simulating fracture in heterogeneous bars, and we are currently in the process of applying this methodology to bone fracture analysis.

Figure 2: Crack location prediction applying PFM on humerus under compression.

There are two main purposes:

- Investigate the applicability of the phase-field method to predict fractures in complex heterogeneous materials.

- Develop an efficient and accurate numerical method for predicting human bone fractures that can be used for medical applications, particularly in preventive surgeries.

Expected Date: September 2025

Public health»: Bone fracture prediction is of significant importance in preventing metastatic and osteoporotic fractures through appropriate surgical interventions. Currently, we are collaborating with the Orthopaedic Oncology department at the Tel Aviv Sourasky Medical Center. They have expressed a keen interest in our solution for preventing bone fractures in patients suffering from metastatic bone diseases.

Research and innovation»: While the phase-field method has demonstrated its promise in predicting fractures in brittle, homogeneous materials, it's worth noting that many materials, such as human bone, exhibit heterogeneous material properties and mechanical behaviors that differ slightly from homogeneous materials. As a result, we are actively exploring the applicability of the phase-field method for such materials. Our aim is to not only enhance its potential for predicting fractures in these complex materials but also to garner greater interest within the scientific community for its use in studying material fractures.

Zeng Liu

“All models are wrong, some are useful.” - George Box

ESR09: Multi-field and multi-scale modeling of fracture for renewable energy applications. See details»

My name is Zeng Liu. I am from China. I am now a PhD student at NewFrac Innovative Training Network (ITN) - supported by the Marie Skłodowska Curie Actions (MSCA) of European Commission at IMT School for Advanced Studies Lucca (Italy) and University of Seville (Spain).

University of Seville, Spain // Duration: 6 months (Sep 2021 - Mar 2022)

My first secondment was conducted in University of Seville from 09/2021 to 3/2022. I developed the phase field model with solid shell formulation for the brittle fracture modeling of very thin solar cells in photovoltaics.

Cubicoff // Duration: 4 months (Apr 2023 - Sep 2023)

My second secondment was conducted in Cubicoff from 26/04/2023 to 01/09/2023. I developed the continuum diffusion-swelling theory to facilitate the design of nondestructive recovery of silicon solar cells in the photovoltaic recycling.

During my PhD, I attended several conferences and workshops, and made the oral presentations.

- CFRAC 2023 - Seventh International Conference on Computational Modelling of Fracture and Failure of Materials and Structures, held in Prague, Czech Republic, from 21st to 23rd June, 2023.

- NewFrac & TC16 Joint Workshop – “Reaching Out”, held in Torino, Italy, from 17th to 20th January, 2023

- ECF23 - European Conference and Summer School on Fracture 2022 held in Funchal, Madeira, Portugal, from 25th June 2022 to 2nd July 2022

- NewFrac Workshop 2 – “Expanding Horizons”, held in Lucca, Italy, from 09th to 12th May, 2022

- NewFrac Workshop 1 – “New Strategies in Computational Fracture Mechanics”, held in Seville, Spain, from 1st to 8th October, 2021

- Zeng Liu, Jose Reinoso, and Marco Paggi. Hygro-thermo-mechanical modeling of thin-walled photovoltaic laminates with polymeric interfaces. Journal of the Mechanics and Physics of Solids, 2022, 169, p.105056. https://doi.org/10.1016/j.jmps.2022.105056»https://doi.org/10.1016/j.jmps.2022.105056»

- Zeng Liu, Jose Reinoso, and Marco Paggi. Phase field modeling of brittle fracture in large-deformation solid shells with the efficient quasi-Newton solution and global–local approach. Computer Methods in Applied Mechanics and Engineering, 2022, 399, p.115410. https://doi.org/10.1016/j.cma.2022.115410»

- Zeng Liu, Jose Reinoso, and Marco Paggi. A humidity dose-CZM formulation to simulate new end-of-life recycling methods for photovoltaic laminates. Engineering Fracture Mechanics, 2022, 259, p.108125. https://doi.org/10.1016/j.engfracmech.2021.108125»

- Zeng Liu, Pietro Lenarda, Jose Reinoso, and Marco Paggi. A multifield coupled thermo-chemo-mechanical theory for the reaction-diffusion modeling in photovoltaics. International Journal for Numerical Methods in Engineering, 2023. http://doi.org/10.1002/nme.7233»

- Zeng Liu, Michele Marino, Jose Reinoso, and Marco Paggi. A continuum large-deformation theory for the coupled modeling of polymer-solvent system with application to PV recycling. International Journal of Engineering Science, 2023, 187, p.103842. https://doi.org/10.1016/j.ijengsci.2023.103842»

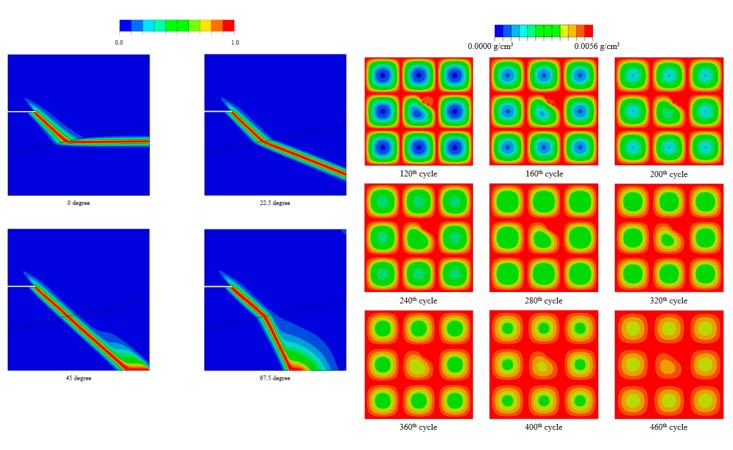

My PhD thesis is mainly focused on the computational modeling of solar cell cracking, multiphyics phenomena, and recycling of photovoltaic (PV) modules through the finite element method. Specifically, it consists of three parts. In the first part, a comprehensive hygro-thermo-mechanical computational framework in the 3D setting is proposed to model the coupled degradation phenomena in the PV modules for the durability analysis, and it is applied to the simulation of three international standard tests of PV modules, namely the damp heat test, the humidity freeze test, and the thermal cycling test. The second part is focused on the crack modeling of very thin and brittle silicon solar cells in the PV modules, and a reliable computational framework integrating solid shell element formulation with phase field fracture modeling is developed using the efficient quasi-Newton solution scheme and global local approach. The excellent performance is showcased through the simulation of different boundary value problems, and then applied to predict the crack growth of silicon solar cells when the PV modules are subjected to different external loadings. The third part addresses the efficient recycling of PV modules through the numerical modeling method by the development of 3D interface finite element with humidity-dose enhanced cohesive zone model for the peeling simulation to separate different layers, and diffusion-swelling large deformation continuum theory for the nondestructive recovery of silicon cells in the PV recycling using the solvent method. With these tools at hand, it is possible to design suitable virtual testing procedures for PV durability and recyclability analysis.

My investigation during my PhD study aims to design the efficient methods for the evaluation of performance and recycling of photovoltaic modules, and so it helps mitigate the environmental pollution.

Date: Defended on 22/03/2024

Link to Open Access Repository: http://e-theses.imtlucca.it/407/»

Presentation: ESR09_Liu_Zeng»

My contribution to EU Policies could be oriented to:

- EUROPEAN GREEN DEAL»: European Green Deal - Consilium (europa.eu)

- CLEAN AND SUSTAINABLE MOBILITY»

My investigation during my PhD study aims to design the efficient methods for the evaluation of performance and recycling of photovoltaic modules, and so it helps mitigate the environmental pollution.

Francesco Vicentini

“There is a crack in everything, that’s how the light gets in”. - Leonard Cohen.

ESR10: PF modeling of fracture in the human femur. See details»

I am a PhD student in computational mechanics and have a strong passion for both mechanics and illustration. I am particularly excited about the unexplored research opportunities in modeling apparently simple everyday phenomena such as fractures, and I want to contribute to this field. I find it fascinating how science and art share a common sense of elegance.

Tel Aviv University // Duration: 6 months (Sep 2022 - Feb 2023)